Comment savoir si une boîte de vitesses est HS ?

Les composants de la mécanique automobile sont majoritairement des pièces sujette à l’usure. Pour cette raison, le carnet d’entretien mentionne la fréquence à laquelle il faut remplacer les éléments en question. On peut citer l’amortisseur, qui doit être changé tous les 80 000 km ou encore les plaquettes de frein dont la durée de vie moyenne est de 30 000 km.

Un service irréprochable

Boite de vitesses cassée ? Nous vous aidons à identifier et commander votre modèle

Découvrez tout ce qu’il y a à savoir sur les indicateurs d’une boîte de vitesses HS !

Boîte de vitesses HS : quels sont les indicateurs ?

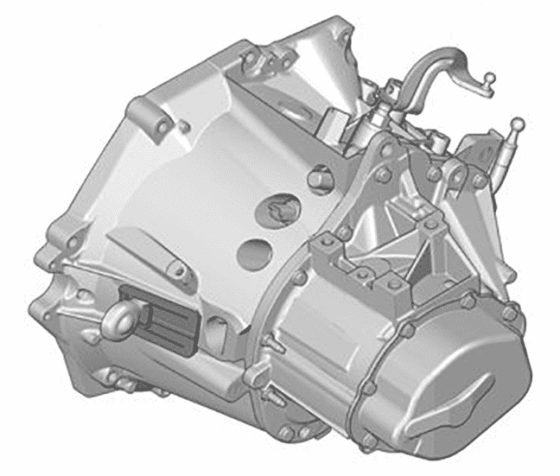

La robustesse de la boîte de vitesses est remarquable. En théorie, cet organe de transmission devrait durer aussi longtemps que la voiture, toutes marques et tous modèles confondus. Cependant, certains facteurs peuvent altérer cette estimation !

Des circonstances imprévues, comme des chocs et des accidents, ou des erreurs d’inattention, telles que l’oubli des révisions et des entretiens périodiques, peuvent réduire sa durée de vie. Ainsi, les performances de la boîte de vitesses diminuent progressivement. Au début, les anomalies sont mineures, mais elles peuvent rapidement s’aggraver. Si vous ne réagissez pas aux premiers symptômes, les composants peuvent être endommagés, rendant la boîte de vitesses inutilisable. Dans ce cas, vous devrez envisager de la remplacer dans une boutique spécialisée. Pour éviter d’en arriver là, soyez attentif aux signes d’usure.

Les défaillances et symptômes dont nous dressons la liste dans cet article sont les plus courants, bien que des anomalies plus rares puissent également survenir. Dès que votre boîte de vitesses présente des changements de comportement, faites-la vérifier rapidement. Vous avez peut-être l’impression que la boîte de vitesses est devenue dure. Ce n’est pas forcément le symptôme d’une casse, mais il est essentiel de mener quelques vérifications. Commencez par contrôler la pédale d’embrayage pour vous assurer que sa course n’est pas gênée par des déchets, du gravier, de la boue ou encore un tapis de sol trop épais ou mal positionné.

Quelques signes avant-coureurs !

Voici les manifestations les plus courantes d’une anomalie dans le fonctionnement de votre boîte de vitesses. Si vous remarquez un ou plusieurs de ces signaux d’alerte, ou d’autres signes anormaux, il est préférable de ne plus utiliser la voiture. Contactez un professionnel et fixez un rendez-vous pour établir un diagnostic de la boîte de vitesses. Voici une liste de quelques indicateurs d’usure qui peuvent vous mettre la puce à l’oreille :

Passage des rapports difficile

Si un seul rapport de vitesses passe mal, cela signifie que l’une des pièces connectées au rapport concerné est défectueuse. Il s’agit généralement du synchroniseur, mais attention, d’autres éléments peuvent également être à l’origine de l’anomalie. Si plusieurs rapports, voire tous les rapports de vitesses sont durs et passent difficilement, l’usure des bagues de synchronisation et les problèmes de tringlerie sont souvent en cause. Ces pièces usées ne sont plus capables d’assurer leur fonction, qui est de transmettre la commande du levier à l’intérieur de la boîte de vitesses pour engager le rapport souhaité. La dureté de plusieurs vitesses peut aussi être due à une défaillance du volant moteur ou du système d’embrayage.

L’engagement des vitesses

Si votre vitesse s’engage normalement, mais a tendance à se désengager d’elle-même, en particulier lorsque vous accélérez, le levier de vitesses se repositionne au point mort sans intervention de votre part. Cela signifie que la vitesse “saute”, ce qui est souvent la conséquence d’une défaillance de la tringlerie ou des synchroniseurs.

Sifflement continu

Si vous entendez une sorte de sifflement provenant de la boîte de vitesses lorsque le régime moteur monte, et que ce bruit disparaît au débrayage, c’est probablement le signe que les roulements sont usés. Ce sont ces pièces qui doivent être remplacées, et non la boîte de vitesses dans son intégralité.

Bruit de craquement

Si des craquements se font systématiquement entendre lorsque vous passez vos rapports, associés ou non à la difficulté d’engager les vitesses, ce symptôme traduit généralement l’usure des synchroniseurs. Les sélecteurs de vitesses peuvent aussi provoquer des craquements lorsque les câbles sont mal réglés.

Ronflement sourd de la boîte

Si vous constatez un ronronnement ou un ronflement sourd à certaines vitesses, il est possible que les dents des pignons soient trop usées. Si votre boîte de vitesses émet un bruit inhabituel lorsque vous accélérez, ou lorsque vous utilisez le frein moteur, il est probable que le souci vienne du différentiel.

Fuite de liquide de transmission

Vérifiez le niveau d’huile de la boîte de vitesses. Si le liquide est insuffisant, les engrenages sont mal lubrifiés, ce qui vous oblige à forcer sur la boîte de vitesses pour qu’elle réagisse à vos manipulations. En parallèle, vérifiez le niveau du liquide d’embrayage.

Si vous remarquez des traces d’huile de boîte sous le carter, cela indique une fuite d’huile de boîte. Le carter est peut-être percé ou mal rebouché. Au début, vous ne constaterez peut-être aucun bruit suspect ni aucun signe lié à la baisse de liquide. Mais si vous laissez traîner le problème, il y a un risque élevé que la boîte de vitesses finisse par se casser. Ne prenez jamais une fuite à la légère !

Défaut de l’embrayage

Si vous remarquez une patine d’embrayage, c’est-à-dire qu’il ne transmet plus efficacement la puissance du moteur aux roues, la boîte de vitesses ou l’embrayage nécessite une inspection.

La BVA

La boîte automatique, aussi appelée “transmission automatique”, n’est pas exempte de problèmes, bien que résultant d’une technologie plus perfectionnée que la boîte manuelle. Parfois, le passage des rapports devient lent ou irrégulier, ce qui peut indiquer une usure du système de double embrayage. Sur le tableau de bord, des voyants peuvent s’allumer pour signaler des problèmes liés à la boîte de vitesses. Soyez vigilant aux symboles inhabituels !

Boîte de vitesses HS : comment la réparer ?

Qu’il s’agisse d’une boîte automatique ou manuelle, il va de soi que toute anomalie doit faire l’objet d’une réparation adéquate. Autrement, vous ne pourrez pas continuer à rouler avec votre véhicule sans risquer d’aggraver les défaillances de la boîte de vitesses. Le premier réflexe que vous devez avoir sera de relever l’ensemble des symptômes, notamment les vitesses défectueuses que vous rencontrez. En effet, si votre boîte de vitesses est défaillante, vous devez alors prendre contact avec un garagiste professionnel et lui faire connaître les signes de défaillance que vous avez notés. Il pourra vous conseiller de conduire le véhicule jusqu’à son atelier ou de faire remorquer la voiture si les symptômes sont susceptibles de traduire des anomalies critiques, voire fatales à votre véhicule.

Étape 2 : La vidange

La vidange de la boîte de vitesses s’effectue généralement avant la dépose. Le cas échéant, le garagiste retire l’huile de boîte après avoir déposé la BV sur son plan de travail. Un nettoyage minutieux est ensuite effectué sur toute la surface externe de la boîte de vitesses. Cette étape s’effectue à l’aide d’un pinceau préalablement trempé dans de l’essence ou du gazole ou au moyen d’un nettoyeur vapeur.

Étape 2 : la dépose de la boîte de vitesses

Afin que votre garagiste affine son diagnostic, il doit procéder à la dépose de la boîte de vitesses, car son analyse dépendra du système de transmission et du type de boîte. Une fois que votre véhicule sera entre les mains du garagiste, il peut entamer les contrôles. Si votre voiture est dotée d’une traction avant, la boîte de vitesses peut se situer devant ou derrière le moteur.

Différents composants internes devront être retirés pour accéder à la boîte de vitesses. Dans certains cas, il faut démonter la calandre, le groupe mototracteur ou encore le radiateur. Si votre véhicule embarque une transmission à propulsion, la dépose de la boîte de vitesses se fait généralement depuis l’habitacle ou par-dessous. En fonction du modèle de boîte de la voiture que vous conduisez, la dépose du moteur pourrait également être nécessaire, afin que le garagiste puisse désolidariser la boîte de vitesses en toute sécurité.

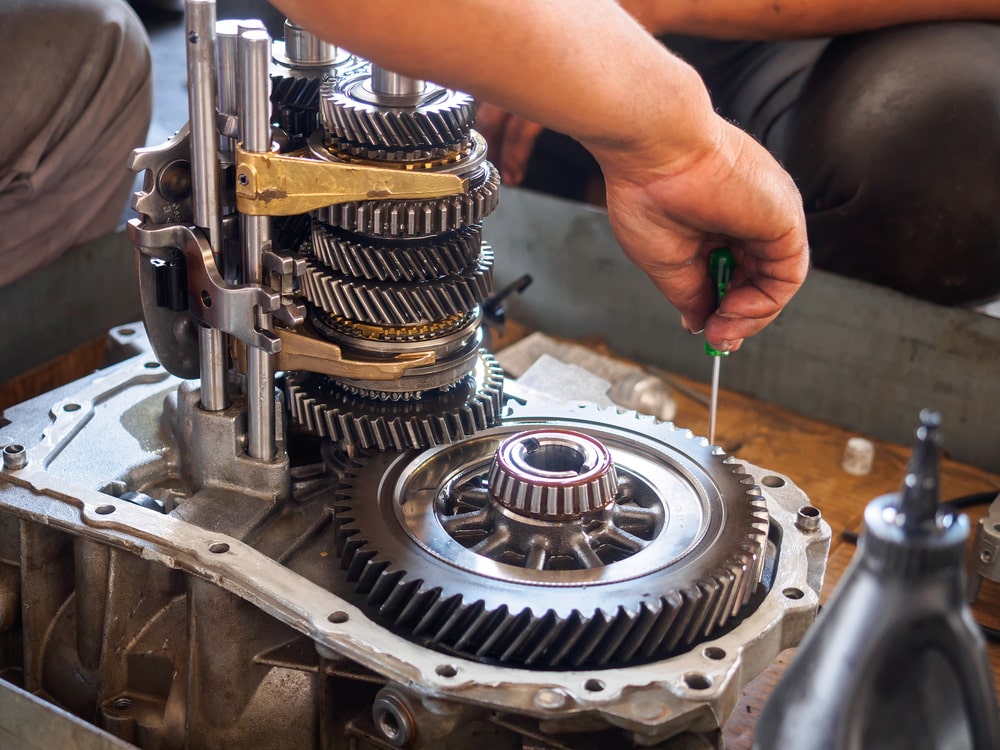

Étape 3 : le démontage de la boîte de vitesses

Une fois la boîte de vitesses déposée et vidangée, le garagiste peut entamer le démontage pour accéder à toutes les pièces, comme le pignon secondaire, les tiges de renvoi, et les composants internes qui seront ensuite inspectés. Il est probable qu’il fasse tourner les arbres de transmission afin d’évaluer l’usure des engrenages. Il vérifiera également que les dents des pignons sont intactes et en bon état.

Parallèlement, il examine la surface d’appui de la pignonnerie pour s’assurer qu’elle ne présente aucun piquage. Cette vérification se poursuit jusqu’à ce que tous les composants de la boîte de vitesses aient été soigneusement inspectés. Le garagiste s’assure de l’absence de jeu et vérifie si la fixation des pièces est correcte. Il contrôle également l’état des joints, vérifie si toutes les vis sont présentes et fonctionnent correctement, et s’assure que les pièces ne sont ni percées, ni fissurées, ni endommagées quelque manière que ce soit..

Étape 4 : le remontage de la boîte vitesses

Une fois que toutes les pièces de la boîte de vitesses ont été inspectées et remises en état (ou remplacées), le garagiste peut procéder au remontage. Pignonnerie, arbre secondaire, joints, carter d’huile : chaque élément est inspecté et fixé avec beaucoup de soin. Le montage s’effectue par ailleurs suivant un ordre spécifique à votre boîte de vitesses. Comme durant la dépose, le garagiste peut toucher à d’autres composants mécaniques afin que la boîte de vitesses soit mise en place dans les règles de l’art.

Étape 5 : remplissage de la boîte de vitesses

Ensuite, le garagiste ajoute de l’huile de transmission, étape essentielle pour garantir une bonne lubrification de la boîte de vitesses dans son ensemble. Après cela, une phase de test s’impose ! Le garagiste doit s’assurer :

- Que les engrenages tournent correctement ;

- Que les passages de vitesses sont silencieux et fluides ;

- Qu’il n’y a pas de fuite d’huile.

D’autres contrôles vont évidemment être effectués, ce qui demande de la minutie, beaucoup de rigueur et une maîtrise impeccable du mécanisme de la boîte de vitesses !

Info pratique !

Concernant les boîtes de vitesses automatiques, elles ne se limitent pas à des éléments mécaniques, elles intègrent également des systèmes électriques et électroniques. Pour cette raison, il est essentiel que le garagiste vérifie le bon fonctionnement de ces composants. Une reprogrammation complète est souvent nécessaire avant que la boîte de vitesses puisse remplir correctement ses fonctions.

Remplacer ou réparer la boîte de vitesses ?

Au fur et à mesure que le garagiste évalue la boîte de vitesses, il identifie les composants défectueux tels que les bagues de synchro, les roulements, et d’autres pièces similaires. Il établit une liste des éléments qui nécessitent un remplacement immédiat et de ceux dont le changement est conseillé.

En fonction des conclusions du diagnostic, le professionnel pourra déterminer s‘il est nécessaire de remplacer la boîte de vitesses endommagée. Avant de procéder à ce remplacement, il est crucial de connaître la référence exacte de la boîte de vitesses pour garantir l’achat d’un modèle compatible. Votre garagiste pourra vous fournir cette information. Si nécessaire, une boîte de remplacement correspondant au modèle spécifique de votre véhicule pourra être trouvée.

Ce n’est qu’après avoir réalisé une série de vérifications et d’essais approfondis que le garagiste sera en mesure de vous restituer une boîte de vitesses pleinement opérationnelle. L’intervention est couverte par une garantie qui vous permettra de parcourir de nombreux kilomètres en toute sérénité.

Avant de reprendre la route, assurez-vous de vous informer sur les entretiens nécessaires et leur fréquence. Gardez à l’esprit que maintenir votre boîte de vitesses en bon état est crucial pour éviter les pannes ! N’hésitez pas à demander à votre garagiste s’il a des conseils supplémentaires pour prévenir les dysfonctionnements.

Boîte de vitesses HS : où trouver une pièce de rechange ?

Vous avez passé la première étape qui vous permettra d’acheter une transmission automatique ou manuelle, c’est-à-dire prendre connaissance de la référence à rechercher. Vous pouvez donc commencer à comparer les offres existantes en prenant soin d’éviter les pièges ! Lorsqu’une boîte de vitesses tombe en panne au point de ne pas pouvoir être réparée, vous devez bien souvent engager un prix assez conséquent pour le remplacement.

Il est tout à fait compréhensible que vous cherchiez en priorité des pièces abordables, mais cela ne doit pas se faire au détriment de la fiabilité du produit. Comme nous l’avons dit plus haut, une boîte de vitesses devrait tenir aussi longtemps que votre véhicule sera utilisé et devrait être opérationnelle sur au moins quelques centaines de milliers de kilomètres.

En ce sens, le choix de votre fournisseur est extrêmement important ! Assurez-vous de passer par une plateforme qui propose exclusivement des boîtes de vitesses testées par des experts et soumises à une garantie pièce.

EDEN BOITES : des offres uniques et des services de qualité

Chez EDEN BOITES, chacun des 12 000 produits disponibles dans nos 7 centres de stockage a préalablement passé une série de contrôles rigoureux et exigeants.

En entrée de gamme, nous vous proposons des boîtes de vitesses d’occasion. Par définition, il s’agit d’organes mécaniques qui ont préalablement servi sur d’autres véhicules, ce qui ne remet pas en question leur fiabilité ! Après une évaluation minutieuse, nos spécialistes définissent la durée de garantie qui correspond à 3 mois minimum, mais qui peut aller au-delà selon les caractéristiques du produit d’occasion. Notez que ces produits ne sont pas adaptés aux véhicules soumis à un usage intense.

Échange standard, reconditionnement, garantie : les solutions proposées par EDEN BOITES

On monte en gamme avec les boîtes de vitesses en échange standard : les tarifs sont plus élevés, mais les performances garanties sont également meilleures ! Cette catégorie de produit est associée à une garantie de 12 mois et s’adapte parfaitement aux usages intensifs. Autrement dit, mieux vaut investir dans une boîte de vitesses manuelle ou une boîte de vitesses automatique en échange standard si vous avez l’habitude d’effectuer de longs trajets ou si vous conduisez régulièrement votre voiture.

Nous prenons soin de réapprovisionner régulièrement notre stock en veillant à ce qu’un large éventail de références soit mis à la disposition de nos clients. Malgré cela, la possibilité que le produit dont vous avez besoin ne soit pas en stock n’est pas écartée… Mais rassurez-vous ! Nous avons une excellente alternative qui vous permet de réduire vos dépenses, de lutter contre le gaspillage et de profiter d’une boîte de vitesses comme neuve : la reconstruction à 0 km de votre pièce défectueuse, ce qu’on appelle plus simplement reconditionnement de la boîte de vitesses.

EDEN BOITES : un expert de la boîte de vitesses

EDEN BOITES occupe une position de leader sur le marché français, mais aussi à l’échelle européenne. Notre succès repose avant tout sur la rigoureuse attention que nous portons à la qualité de nos boîtes de vitesses, tout en offrant des prix compétitifs qui vous permettent de contrôler les coûts de remise en état. De plus, nous couvrons l’ensemble du continent européen. Que vous fournissiez une adresse en France ou dans un autre pays européen, nous nous engageons à ce que votre boîte de vitesses soit expédiée rapidement par des transporteurs expérimentés.

N’attendez pas que les défaillances de votre boîte de vitesses soient plus graves pour demander votre devis gratuit ! Vous recevrez rapidement une offre personnalisée et sans engagement par retour d’e-mail. La proposition vous convient ? Validez votre commande et profitez des nombreuses solutions de paiement sécurisées que nous mettons à votre disposition. Votre boîte de vitesses défaillante ne sera bientôt qu’un mauvais et lointain souvenir et vous pourrez à nouveau reprendre la route l’esprit tranquille !