How do I repair a gearbox?

The gearbox (BV) is one of the main main components that enables your vehicle to move forwards and backwards. Its job is to reduce or increase the driving force to match the speed of the wheels. On all types of vehicle, the gearbox is responsible for transfers power from the engine to the wheels, enabling the car to move. Numerous faults can affect the gearbox operation : it's essential to know how to repair your manual or automatic gearbox!

Impeccable service

Gearbox broken? We help you identify and order your model

How do I know if a repair is necessary?

The gearbox is designed for a long service life equivalent to that of your car, at least under normal conditions of use. It should therefore last at least 300,000 km.

Signs of wear on a manual gearbox

In practice, various factors can reduce this remarkable longevity, such as :

- Aggressive or abrupt behaviour ;

- Neglect of gearbox checks and maintenance (checking fluid levels, topping up oil, changing oil, etc.);

- Shocks repeatedly ;

- Use of excessive force when operating the gearshift lever;

- A malfunction in the mechatronic system;

- Road conditions.

Gearbox problems rarely go unnoticed. and should be taken into consideration to optimize the life of your gearbox.. In fact, there are many signs help you identify the presence of a fault. Ey paying attentionyou'll easily spot them.

Indicators of wear and tear can be heard in the form of noises, such as continuous whirring.. This usually means that the bearings mounted on the drive shafts are in poor condition: there's a risk of them breaking and destroying the entire BV.

If it becomes impossible to engage the gearshift lever in one or more positions, the gear selection system is probably blocked or the linkage has failed. Lack of oil or dirt may also be the cause. may also be to blame.

You hear creaking when shifting gears or gear engagement becomes complicated? This may be a sign that the synchros are worn or that the gears are not sufficiently lubricated, preventing them from meshing with the pinions.

Symptoms may also vary according to depending different types of gearbox. In most cases, failure of a manual BV are manifested by difficulty in changing gear ratios, or the feeling that the gearbox is hard, leaving you with the impression that it's resisting you. It may also be the case that gears skip or the transmission system becomes abnormally noisy. Finally, in some cases you may notice oil leaks under the gearbox housing.

Signs of wear on an automatic gearbox

For automatic gearboxes automaticyou need to be vigilant if you notice jerking during starting and acceleration. Similarly, it's a good idea to have your BVA checked quickly if you hear any grunting or squeaking noises that seem to be coming from your gearbox. Difficulty downshifting and loss of power are also warning signs to be heeded.

That's for sure, these signs of malfunction are not exhaustive. If they do occur, or if you notice any other form of malfunction, make an appointment immediately with a qualified mechanic. Driving a car with a BV that is not at its best is a risk for the vehicle's occupants and the driver. a risk to vehicle occupants and other road users. Add to this the fact that minor faults may be amplified and spread to other gearbox components, resulting in more serious failures that are more difficult to repair, and therefore more likely to cause serious damage.more difficult to repair, and consequently more costly..

How do you identify the right type of gearbox?

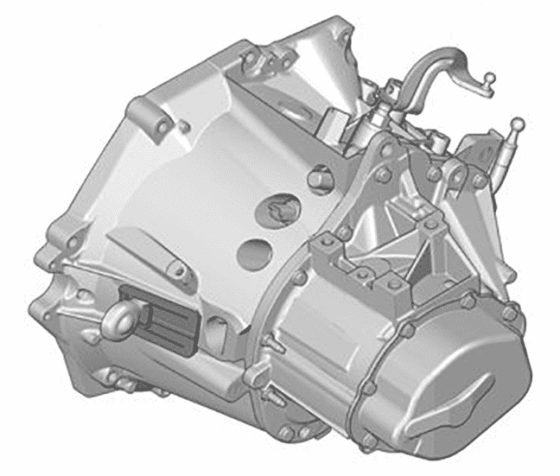

The gearbox can be considered the core of the core of the transmission system, since it links the the wheels and the engine of a vehicle. There are several several types of gearbox mechanical and automatic.

The manual manual is the most common on the European continent: it features a series of gears that enable the driver to select a gear by operating the gearshift lever while depressing the clutch pedal. In other words, the driver's intervention is for every gear change. ! The 5-speed manual gearboxes and 6-speed gearboxes are in the majority on the automotive market. However, it is possible that your vehicle may have up to 7 speeds manual gearboxes.

Gearbox operation

BVMs all work on the same principle same principle : l'input tree called also known as the main or primary shaft, is connected to the motor via the clutch system, and transmits its rotation to the intermediate shaft, which in turn drives the secondary shaft. The secondary shaft carries the pinions linked to the transmission ratios.

When you operate the gearshift, the linkage transmits the command to the gearbox. the gearbox. A fork will then move, triggering the movement The gearshift lever slides until the pinion corresponding to the selected gear ratio locks onto the secondary shaft.

Extremely popular in the American and Asian marketsautomatic gearboxes are becoming increasingly popular in Europe. Manufacturers generally offer them as optional extras, but some models are supplied with with an automatic gearbox. They differ from manual gearboxes by the fact that the driver does not need to intervene, and by the absence of a clutch pedal.. The number of gears is also higher on this type of gearbox. Although the norm is around 6 automatic gears, BVAs can have as many as up to 9 or 6 gears.

The different positions on the automatic gearbox

Another element can also be associated with the overall mechanism of automatic gearboxes: the gearshift. However, its function is not to engage a gear, its function is not to engage a gear. Each position in the gearshift gate determines a driving mode on which the system selects transmission gears. The standard positions of the automatic gearbox are as follows:

- P = Parking : lhe wheels of your car are blocked when you activate this mode;

- R = Reverse : cThis is the position to select before reversing;

- N = Neutral : lhe vehicle is in neutral. Its wheels may turn;

- D = Drive : lhe gearbox is in forward mode. The system analyzes driving conditions and selects gears without your intervention;

- S = Sport is an additional mode found on many cars designed for sporty driving;

- W = Winter : is a useful mode when the wheels are slipping. Start-ups on ice and other slippery surfaces are carried out in second gear ;

- 1 = your vehicle is in first gear only;

- 2 = automatic gearbox alternates between first and second gear ;

- 3 = available on certain vehicles, it allows the transmission system to alternate between the first three gears.

Sequential gearboxes are not a type of gearbox in the strict sense of the term. additional function inherited from Formula 1 transmissions! Like the automatic gearbox, it has no clutch pedal. Instead, the driver selects controls via a steering-wheel-mounted steering-wheel-mounted paddle-shift or by operating a gearshift lever.

The robotized gearbox is a hybrid version.version, as it is basically a mechanical gearbox.. However, its design also includes an automated management system. So you can switch between manual and automatic gear selection with ease!

Visit gearboxes are interchangeable, as each type of gearbox is manufactured according to a specific architectureEach type of gearbox is manufactured to a specific architecture, according to a particular vehicle model and to standards adapted to the car's operating conditions. What's more, automakers tend to evolve their transmissions as new generations of a given model are launched. So it's essential to know which type of gearbox your vehicle is equipped with and which part number corresponds to it.

The model number is a reference code stamped on the housing. In some cases, the manufacturer may write it on a label. This series of numbers or letters will enable you toformally identify which components are compatible with your gearbox for repair purposes. It's also the same reference that should be taken into account if replacement is essential.

How is the gearbox repaired?

Have you noted the signs of malfunction? ? That's a great start ! Now you need to contact a professional professional and clearly explain the shortcomings you've noticed.

Diagnosis

Breakdowns do not always justify gearbox replacement. Refurbishment is sometimes possible, depending on the degree of wear of the componentsthe extent of breakage and other characteristics of the problem encountered. In other words, the diagnosis of the gearbox is the first first step of a quality repair.

Howeverthe duration of the diagnosis is random, because this is a complex taskit may take 5 minutes for the mechanic to identify the cause of the malfunction, or it may take up to two hours for the mechanic to identify the cause of the malfunction. take a few days before he can give you a reliable diagnosis. There may be several elements and in some cases, functional tests and visual inspections reveal nothing. This is when you need to dismantle the box!

Dismantling

Disassembly is not for everyone, This task requires specific specific mechanical and special special tools. You need to remove the center console, remove the gearshift, unscrew the bolts holding the driveshafts in place, disconnect the gear sensors... The steps to be followed depend on the gearbox model. The tools used during removal must be carefully selected to allow parts to be disassembled without damaging anything.

Identify and dismantle defective components

After removing the gearbox, the professional can carry out a closer inspection to look for signs of wear and deterioration likely to have caused the anomalies observed. He can also identify elements which may have gone unnoticed, but which could, in the longer term, damage the gearbox.

When it is possible to repair the gearbox, the garage undertakes the overhaul, by draining the gearbox to remove the dirt that has built up over time, thus preventing malfunctions from recurring or new ones from appearing.. In the event of critical failures, he will choose to replace the gearbox with a used model or a standard exchange.

Assembly

Assembling a BVM is tediousyou have to reposition the gear train and axle, fix the bearings, position the transmission, etc. The seals and screws to be used vary from model to model, and there's no point in making a mistake, otherwise the gearbox's efficiency will be compromised. Once the gearbox has been correctly reassembled, the housing is filled with fresh oil. The garage then proceeds to a test phase by shifting the gears one by one, to ensure that the malfunctions have completely disappeared and that the gearbox is ready for safe use. safe to use.

In the case of an automatic gearbox, it's not enough to follow the removal and installation steps to the letter. In addition to the necessary checks and tests, reprogramming the reprogramming of the system is usually required.

Please note that these steps are provided as a guide to help you understand the repair and replacement process. If you are not a trained mechanic, you should never attempt to apply them.. It is imperative that you call in a professional who will judge whether the procedures outlined above are suitable, or whether it is necessary toadjust the method according to the constraints imposed by the condition and properties of your gearbox.

So don't hesitate to ask for several quotes and thefrom different professionals before proceeding with a gearbox replacement or repair. Serious offers are no obligationThis gives you the freedom to entrust the repair of your gearbox to the professional whose offer suits you best. What's more, you're under no obligation you are under no obligation to delegate the purchase of a gearbox to a professional.It's even preferable to do it yourself, by buying the part on the Internet, so you can combine the most advantageous lowest prices with the best quality. This way, you'll benefit from a reconditioned part at a lower price, with the garage taking care of the labor only.

Where and how to buy a quality gearbox?

The mechanic has confirmed that the only solution is to replace the gearbox. This is a significant investmentbecause it's not a part that wears out regularly, unlike other car components. Replacements are only necessary in rare cases, and the gearbox should maintain its performance for as long as you use the car.

Which supplier to choose?

While the cost of labor is freely determined by the mechanic, the price of the replacement product depends on its characteristics. It is therefore impossible to give you an exact price for such an operation.. For this reason, you should place your trust exclusively with gearbox specialists who offer references compatible with all types, models and makes of vehicle. EDEN BOITES has over 12,000 products in stock, and you benefit from terms and conditions of sale and warranty terms and conditions!

The ranges offered by EDEN BOITES

Three gearbox of gearboxes are available; used gearboxes are the the least expensive. Despite previous use, used BVs are functional and reliable, because our experts have checked them individually meticulously. Standard exchange gearboxes are more expensive, but also more efficient, which means a longer warranty period than used models.

A guarantee is offered offered for every product we sell and prices are also displayed in full transparency. If you order an in-stock product, the personalized quote is mainly used to inform you about shipping costs and order details.

If you find yourself in a situation where the model corresponding to your gearbox, whether manual or automatic, is not available, we can help you take advantage of a third range. we can offer you a third range, namely a reconditioned gearbox. reconditioned. In this case,EDEN BOITES will send professional professional transporters to collect the gearbox from your home. Once your gearbox has arrived at our workshop, our technicians set about rebuilding it. rebuilding. More specifically, the gearbox is restored to the technical characteristics of a new product once the estimate.

If we make it a point of honor to select our partners according to very high standards, the carriers we engage are no exception to this rule. They cover a vast area, enabling them to deliver gearboxes to addresses in France and other European countries. The security of your parcel is guaranteed, and we make sure that waiting times are as short as possible, so that the mechanic can quickly take care of the overhaul of your gearbox and consequently your vehicle.