The gearboxan essential part of a vehicle's drivetrain, plays a key role in driving performance and driving efficiency.. By modulating the power transmitted from the engine to the wheels according to need, it ensures smooth driving adapted to different road conditions. But how exactly does this essential mechanism work?

Impeccable service

Gearbox broken? We help you identify and order your model

What is a gearbox?

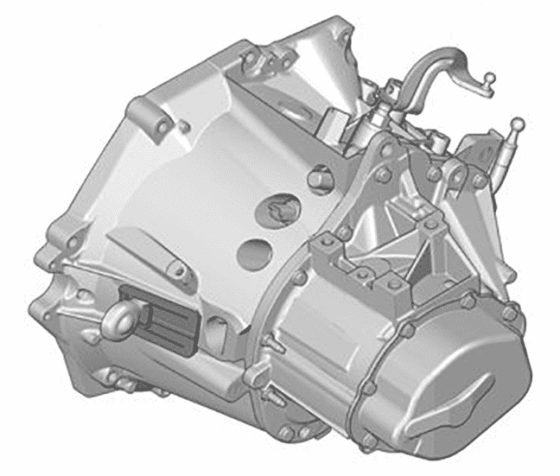

The gearbox is a complex mechanical device located between the engine and the drive wheels of a vehicle. Its main role is to adapt the engine's rotation speed to that of the wheels, enabling the vehicle to move efficiently in a variety of driving conditions.

By adjusting the ratio between engine speed and wheel speed, the gearbox optimizes the power and torque transmitted, resulting in improved acceleration or deceleration. It also enables the vehicle to reverse and remain stationary with the engine running.

There are two main types of gearbox:

- the manual gearboxestraditional manual gearboxes: the driver has total control over gear changes, by depressing the clutch pedal and shifting manually;

- the automatic gearboxes automatic gearboxes: they manage gear changes autonomously, offering more comfortable, smoother and more economical driving.

There are also sequential gearboxes. These modern gearboxes offer a hybrid solution, combining control and driver comfort. Gear changes are made without depressing the clutch pedal, either via steering-wheel-mounted paddles or by using the "+" and "-" positions on an automatic-type lever.

Gearbox operation: what are the gearbox components?

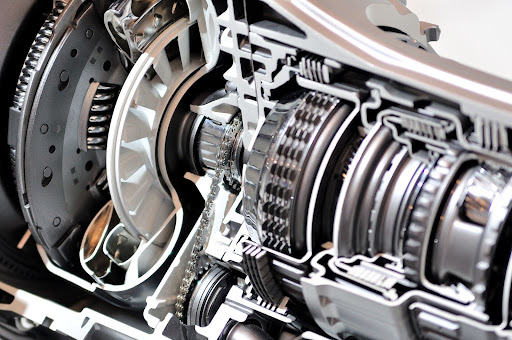

A gearbox is made up of several essential components which work in synergy to ensure ensure its smooth operation. Although they vary according to the type of gearbox, the main components are :

- l'primary shaft connected to the motor, it receives the initial power;

- l'secondary shaft This transmission shaft transmits power to the wheels after adjusting the gear ratio;

- the pinionswhich are gears of different sizes that enable different speed ratios;

- synchronizers They facilitate smooth gear engagement by equalizing rotation speeds;

- the housingwhich is a protective envelope containing all components and lubricating oil;

- the gearshift In manual gearboxes, it allows the driver to select the desired gear; in automatic gearboxes, it is used to select the driving mode (P, R, N, D);

- the clutch clutch: only found in vehicles with manual gearboxes. It connects and disconnects the engine from the transmission;

- torque converter present only in vehicles with automatic gearboxes, replaces the clutch and comprises a pump linked to the engine, a turbine connected to the gearboxand a stator between the two.

How does a manual gearbox work?

The operation of a mechanical gearbox is based on the interaction between several mechanical components, orchestrated by the driver:

- the clutch When the clutch pedal is depressed, the driver temporarily disconnects the engine from the gearbox. gearbox. This action is necessary to change gear without damaging the gears;

- gear selection The driver uses the gearshift to engage the gear corresponding to the desired ratio. This movement moves the selector forks inside the gearbox;

- synchronization Synchronizers come into play to equalize the rotation speed of the gears to be engaged, enabling a smooth gear change;

- engagement Once the gears are synchronized, the pinions mesh, establishing the new transmission ratio;

- Clutch disengagement The driver gradually releases the clutch pedal, reconnecting the engine to the gearbox. gearbox.

This process adapts engine speed to vehicle speed, optimizing the power transmitted to the wheels. The various ratios offer a balance between engine torque and speed, adapting to different driving conditions: starting, acceleration, cruising or climbing.

The driver's control of this mechanism enables precise precise management of the vehicle's powerand often greater fuel efficiency.

How does an automatic gearbox work?

When automatic, the gearbox operates autonomously, with no direct intervention by the driver to change gears. Its operation is based on several key elements:

- the torque converter replacing the clutch on manual gearboxes, it transmits engine power to the gearbox via a hydraulic fluid. It ensures smooth transmission and prevents engine stalling;

- the epicyclic gear This is a set of gears that allows different transmission ratios to be created without disengaging the clutch;

- the hydraulic clutches and brakes activated by oil pressure, they control the epicyclic gear elements to change gears;

- electronic control unit (ECU) The brains behind the automatic gearbox, the ECU analyzes data such as vehicle speed, engine speed and gas pedal position in real time to determine the optimum moment to change gear;

- the hydraulic pump provides the oil pressure required to operate operation clutches and brakes.

The gear change process is as follows:

- UCE evaluates driving conditions;

- controls activation or deactivation of appropriate clutches and brakes;

- the planetary gear adjusts to create the new ratio;

- the torque converter ensures a smooth transition.

This gearbox offers smooth, comfortable driving, automatically adapting gearshifts to driving conditions, while optimizing performance and fuel consumption.

Gearbox maintenance and replacement

The service life of a gearbox can vary considerably depending on vehicle use and maintenance. Although designed to last, gearboxes are one of the most heavily used mechanical components on a vehicle, and may sometimes need to be replaced.

It's essential to know when to change your gearbox to avoid more serious breakdowns. Signs such as unusual noises, difficulty shifting gears or oil leaks can indicate premature wear of the transmission and should alert you. At the slightest suspicion of failure, consult a professional who can assess the condition of your transmission and determine whether replacement is necessary.

EDEN BOITES offers a variety of solutions to meet this need. In addition to conventional replacement, we offer astandard gearbox exchange service. This cost-effective option enables you to acquire a quality reconditioned transmission, while benefiting from the free trade-in of your old gearbox. It's a cost-effective alternative that combines performance and savings when it comes to repairing your vehicle.